Stress grading | Definition | Explanation | Timber

Stress grade is a classification of wood used in structural applications and described in the AS1720 SAA-Timber Structures Code. Stress grades are derived from visual- or machine-grading, which specifies the thresholds of pressure applied to trees used for structural applications.

Building rules now require that all trees used for structural purposes be graded by pressure, so it is important to understand the meaning of the term even if the intricacies of the technique are not.

Since wood is a natural substance it can change in any of its properties, from the same log to the same pallets of saws, or even planks. Compare this with steel products such as beam-columns and joists.

All of these are made of materials of known sizes and shapes, whose properties are closely controlled and completely predictable. When we specify grade 43 steel, we can be sure that the final fiber stress of that steel is the same as that of other parts of grade 43 steel.

So the structural engineer can calculate exactly what size steel to use when building anything from a block of flats to a chemical engineering plant. Prior to pressure grading, it was difficult to design wooden structures without providing high cross-section sizes, to ensure that the structure remained standing.

The wood engineer must be very conservative with the stresses he assumes to bear the tree. The first attempts to remedy this problem saw the weakening of the tree:

1. Nodules. The size and condition of the knots in particular – small and tightly fastened to the tree were not a big problem but were large and loose or missing serious defects.

Also, the position of the knots in the cross-section of the tree was important. If a small tapered knot on the top of the tree or even a tree is too pressed, it will ‘pop’ and weaken the tree.

2. Shakes and splits. This gap moves with the grain of the wood means fibers

Are no longer in contact with each other. This will certainly weaken the tree but if they occur in length this may mitigate their effects.

3. The vane reduces the overall cross-section and thus weakens the wood.

4. That is because insect and fungal attacks prevent the use of a piece of wood

The sound can be seen on the outside, with only a few pinholes or paint, and no one can see inside the board or board.

Most of the insects can take the inside of the cardboard and hardly leave any marks on the surface. Similarly, fungal attacks can spread into the tree, but the more serious consequence is that if the MC exceeds 20%, the tree is vulnerable to further attacks.

Stress grading using machines is now the norm, for certain classes or grades and for some purposes visual inspections. Machines operate on one of two principles:

1. Apply a known load to the length of the tree along a pair of rollers and measure the amount Through it the wood deflects between those rollers

2. Apply the load to rotate the tree by a set amount and record the required load.

The first type is used in the UK and the second type is used in North America.

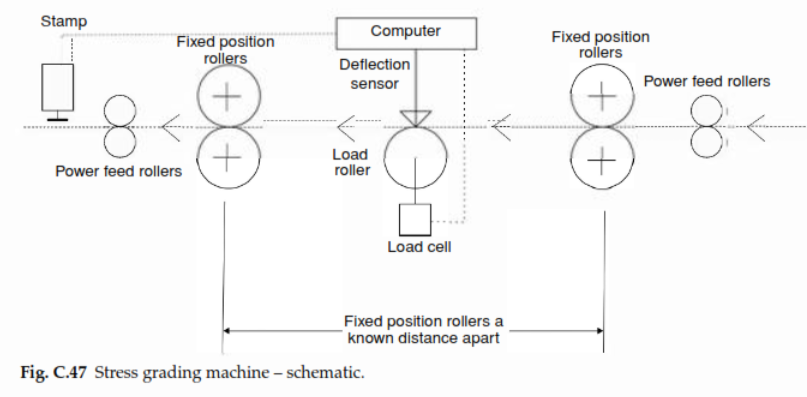

Figure C.47 shows the schematic of a typical pressure grading machine, which contains

The power of the tree is fed into it. Once the load is applied to the wood position, readings are taken and the fiber pressure of the tree is calculated, then the machine seals the grade on the wood.

Putting it this way is quite simple, but the current standards mark 15 separate grades.

Any length of the tree is therefore the lowest grade that can be retained and must be stamped on it.

At least three companies are offering these machines in the UK market. Everything is different, all have their advantages and disadvantages and only five machines are fully accepted in accordance with BS 4978.

Watch This For a Better Understanding:

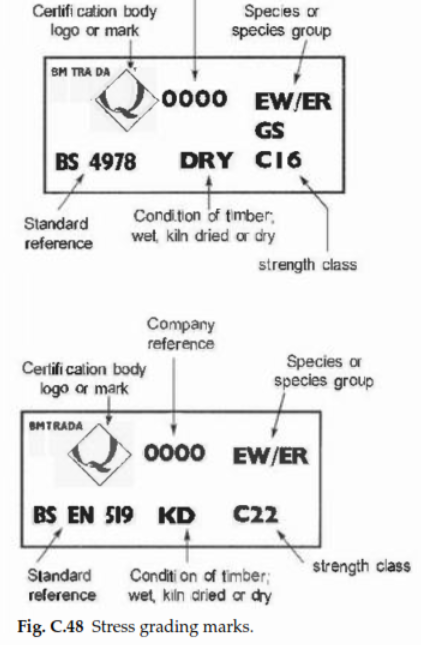

The idea of permanently recording a grade on a tree is very important. It assures the design engineer that the correct timber has been used and that the timber is specified for the building contractor, client, and building control officer.

Figure C.48 shows two typical stamps of UK-grade wood. It should be noted that in order to comply with BS 4978, the tree must include a mark grade and species stamped on it.

Building rules now include load/span tables for structural woodworkers such as joists, roof timbers, and structural sections, so designers must set the expected load with the intended span and select the specific timber size for the grade.

Also Read:

1 thought on “Stress grading | Definition | Explanation | Timber”