Floor Boarding | What Is Floor Boarding?

A floor boarding is one of the usually wooden planks that make up a floor. … This sense of the word is the basis of the slang verb floorboard, meaning to press a vehicle’s accelerator (gas pedal) as far down as possible (all the way to the floor) in order to go as fast as possible.

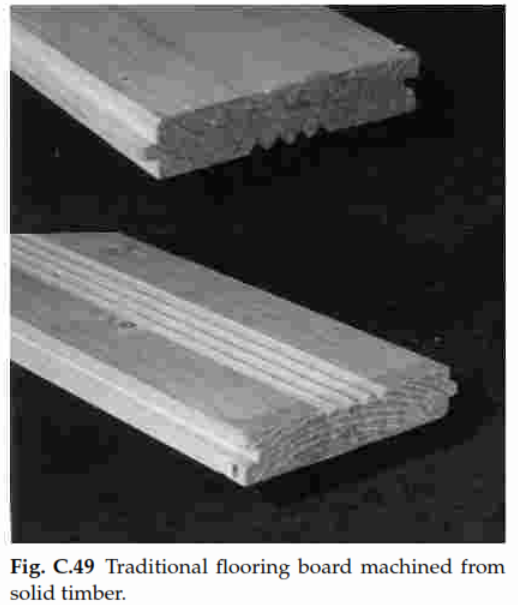

Traditional floor boarding is still available, The kind that stays in long lengths and narrow widths Long groove of tongue and opposite Margins. Figure C.49 shows a conventional flooring Board made of solid wood.

Note on The upper part of the figure, as well as the tongue And the groove, the board has a V-shaped series of Grooves at the bottom. These reduce tensions Onboard while drying and help Reduce cup and bow trends.

The currently available thicknesses vary 16 to 32 and can be supplied almost exclusively

Any length. One cannot be certain about availability, Because mills are the only limit-

Usually has a range of thicknesses and lengths Called in their area.

A mill came near The subject has only two thicknesses in stock, 19 and 27, the first and second to the new work For renovations in the old buildings in the area. Available face widths 90 and 19 for 115 140.

lengths for boards and 27 thick boards The inventory is 4.20, 4.50, and 4.80 m. Manufactured board materials are now widespread Used to float on joists or batons and

Also to provide floating floors on insulation Where the sheets are glued together.

Plywood One of the first objects to be given the Antung and grooved joint in all four edges, and Standard sized sheets (2440×1220) were Before receiving this treatment. These are US Too expensive to produce and compete With traditional floorboards in the UK. They are Still the supreme rule in North America.

Installation Of Laminate Flooring

It wasn’t Until the introduction of a homemade arena Boards 3 It is a product that can compete Brought to the market with floor plates. It is now made in 2400 stock sizes Is long × 600 wide and the most common type Has a two-sided tongue machine Groove on faces and other adjacent faces.

Available thicknesses 19 and 22. The object is made by taking debarked logs And shredding the tree into particles Bound with resin and hydraulically pressed It is ultimately a continuous sheet of material Cut into suboptimal suitable sizes Production line function.

The final act Tongue and grooves machine. Putting Below the particles is not a random act. The outer faces of the sheet are made of finer Particles pressed down to give a harder surface, The center is composed of coarse particles a Lightweight center to the sheet.

The sheet can also be Treated to characterize moisture-resistant (MR). This is not to say that the sheet can sink In the water and not hurt – instead, It is not damaged by surface wetting Solid water is reasonably cleared from the surface Quickly.

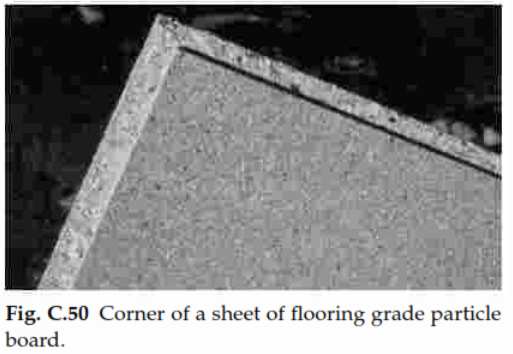

Prolonged wetness can result in Permanent swelling of the object, as we have already counted. Figure C.50 is a corner photograph Flooring-grade particleboard sheet, showing

Top surface.

Fixing down joists or batons Improved nails, perhaps ring shank nails, the Four 600-wide sails are the norm For every joist. Alternatively, the sheet can be Screw-down, again four screws per joist 600 in width.

Only screwing, of course Using power screwdrivers and a specially done Automatic feed holder to integrate Screws. Power nails are used for large Workers of home builders/developers, and For screwdrivers, composite nails are used.

All Those who work must press the nose 3 Particleboard is the preferred term for a board made by aboard Bound with wood chippings or particles and resin and Pressed into sheets of different sizes.

The tool against the floor sheet and this Unlock the safety mechanism. Pulling the trigger

Then runs the nail or screw through the foil For the lower joist – less than a second per nail Screw.

Stacked nails have an improved pattern, There is usually square twisted shanks Ring shank is much tougher than nails That would be easy. Figure C.51 shows the fixing with four Nails in width across the joist or batten.

Nails, screws, and other fasteners are discussed And are described in Appendix G. The t & g all-around facility is Can be placed across joists without boarding The ends fall on the joist, thus reducing the waste.

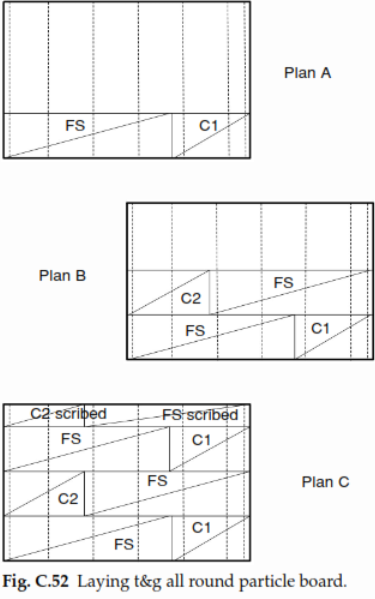

It is much faster to park and thus almost eliminated The floorboards are entirely from the domestic market. Figure C.52 shows how it is laid out, minimized Waste and all internal sections are built From its surface.

When putting these boards on, the carpenter is always on LH (left-hand) corner, starting in places The foil’s tongue adjusts to the side of the room and Below it. On Plan A, the carpenters have placed The first full sheet, FS, in the lower LH corner Of the building. Then they cut the sheet

The LH end of the sheet fits into the C1 space. It has A Groove on the LH end that fits on the tongue At the RH end of the first FS. In Plan B, Bit Leaving C1 to be cut from the full sheet On the LH side of the room (C2).

The cut is the end Ready to receive wall and groove edge The next sheet is marked as a full sheet But one part may be less. If so, narrow The strip cut-off is rejected. On Plan C, potting Continues with the FS laid on the edge of the LH The floorboards have already been laid and the cut C1 has been laid Next, cut the edge of the wall on the right.

From C2 The cutting is then cut wide – written – But only the edge of the tongue should be removed We need a groove to fit on the edge Previous languages. Finally, a full sheet is written Lay with wall and groove edge Previous languages.

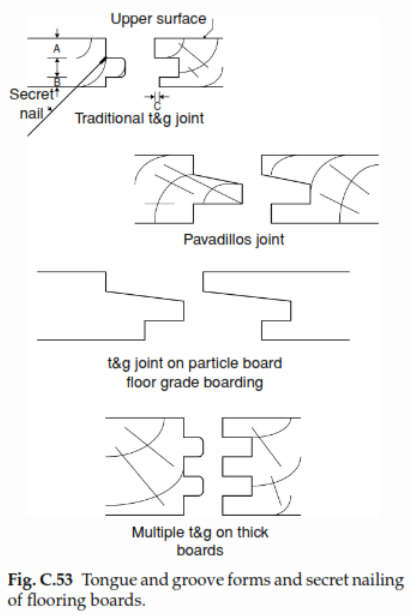

Quite simple and logical Once you get it working. Tongue and groove boards matter

Innovation as long as the joint It was all around. Figure C.53 shows just a few of The forms adopted at one time or another, as well as the secret nail of the tongue and how

Grooved floorboards are held.

Nails As described in Appendix G. The above illustration in Figure C.53 is an A slightly exaggerated form of the modern language On the left side of the sketch; The Tongue

It shows that there is more board on the edge Tongue below it. It is quite deliberate.

There is a worn surface on the tongue Of the board, and it must be worn down After all, there’s not much wood on the tongue Beneath it, there is no dress. Also, And On that side of the sketch is shown a hammer with a hammer House at the angle of projection of the tongue.

There No hammer was made or a carpenter alive Strike the nail to that position with it

Bare hammer. The nail is hammered close to That position and then a punch – a nail set – is Was placed on the head and struck with a blow Run down the nail so that the head is fully present Into the tree.

Having a larger than B allows A little grip on the nail board and somewhere Stay in the head. The groove on the right is shown with the bottom piece Cut from the top. It allows

Board joint to close on the top face without Must collect dirt under so much effort Board Joint on Joist.

Also Read: