GAP GRADED CONCRETE

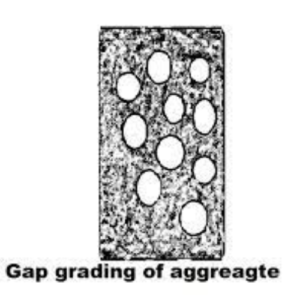

Gap grading is defined as grading where one or more intermediate-size fractions are absent. This type of concrete is obtained when gap-graded aggregates are used in concrete production. In the case of spaced hierarchies, some undesirable size aggregates are omitted from conventional continuous hierarchies.

Undesirable sizes prevent the effective packing of other sizes. Sometimes only available one-size totals are used.

Gap-grading is usually aimed at empowering total efficient packing. A well-packed aggregate requires minimal cement paste to fill small voids.

For the sake of discussion, consider the mathematical model of a sphere of diameter as a sphere of diameter known as the principal spheres. The multitude of these spheres has a rhombohedral form of packing.

The vacancies between the major spheres can be fitted with spheres of 0.414 D diameter, known as the main occupational spheres. The Fine aggregate consists of small industrial spheres that are mathematically 0.225 D in diameter that fit the remaining voids.

The remaining small zeros can now be fitted with 0.155 D diameter access spheres, and these can be provided by a good amount.

Cement paste occupies the remaining voids and produces the perfect compact mixture of mathematics.

However, such a mixture cannot be cast experimentally, and as a result, only the main and entry spheres in the mixed design are considered practical. Therefore, mixtures are usually designed with single-sized aggregate and sand, with all of their particles passing through compressed coarse aggregate zeros.

You may also like: Roller compacted concrete

However, sand particles should not be small enough to block the surface area coated with cement paste. Regardless of the calculations suggested above, the sand content should be sufficient to uniformly distribute throughout the mixture under experimental conditions.

The viability can be increased by reducing the surface area of all ingredients in a unit volume. This can be achieved by using a larger amount of aggregate to accommodate other constraints.

Gap grading causes shrinkage of thin and dry mixtures less than conventional concrete of equal strength.

However, thin mixing makes vibration almost necessary. The compressive forces on the inter-grade concrete spread from the particle to the coarse aggregate particle and not through the cement sand matrix.

As a result, the creep associated with such concrete is low. With the use of single-sized aggregates, the trend of segregation is examined.

Several investigators have recommended the use of two single-sized coarse aggregates with sand and cement in an inter-range blend.

Due to the effective packing of aggregates in inter-tier concrete, vertical shuttering can be removed shortly after casting. However, distance stratification is very sensitive to undesirable particles and the obtained mixture is less efficient.

You may also like: Well graded concrete