FLAKINESS AND ELONGATION INDEX OF AGGREGATE

AIM OF THE EXPERIMENT:

To determine the Flakiness Index of the given sample of course aggregate.

1. Objective:

Particle form and surface texture greatly influence the properties of freshly mixed concrete Characteristics of hardened concrete. Coarse, angular, and elongated particles need additional water to provide a possible concrete instead of a sleek, rounded compact combination. As a result, cement content should be magnified to take care of the water-cement quantitative relation. Generally, flat and long Particles are avoided or confined to regarding V-J Day of the whole weight.

2. Apparatus Required:

Fig. 1: Balance

The balance should be able to weigh up to 1 g.

Fig. 2: Sieves

Sieves required are 63, 50, 40, 31.5, 25, 20, 16, 12.5, 10 and 6.3 mm (Based

on requirement and Gradation of Aggregate).

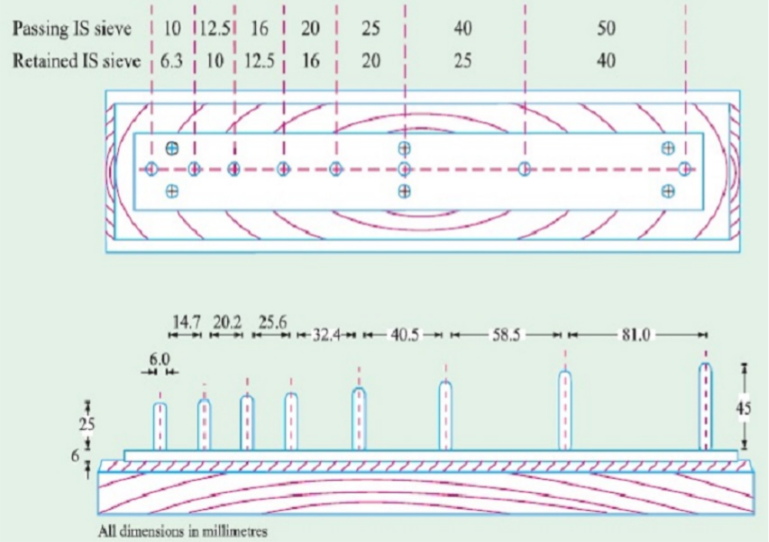

Fig. 3: Thickness Gauge- For Flakiness Index

Thickness Gauge has a width equal to 0.6 times the mean dimension of the aggregate.

Fig. 4: Length Gauge- For Elongation Index

Length Gauge have a length equal to 1.8 times the mean dimension of the aggregate

3. Reference:

IS 2386(Part 1):1963 ways of check for Aggregates of Concrete- Particle Size and form. ReaffirmedDec 2016

4. Procedure:

1. The total amount should be sufficient to provide at least 200 pieces of any fraction to be tested.

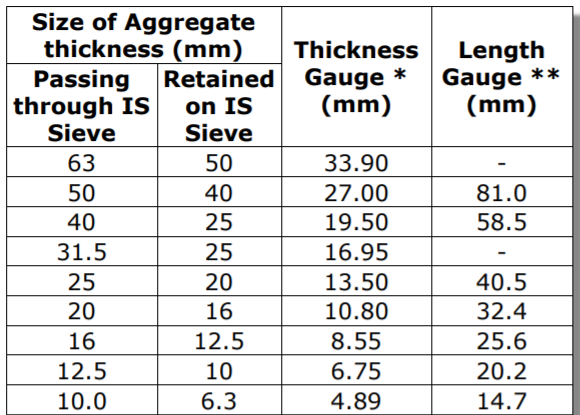

2. Sieve the sample with the sieves specified in Table 1:

* This dimension is capable zero.6 times the mean Sieve size

** This dimension is a capable one.8 times the mean Sieve size

Table 1: Dimensions (Length and Thickness) of Gauges

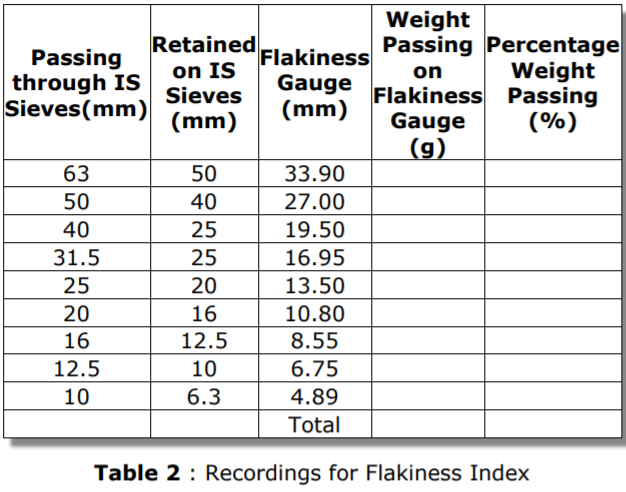

3. Isolation of flaky material – Each section is measured in thickness in a metal gauge of the pattern shown in Fig. 3 or in large quantities on sieves with long slots. The width of the slot used in the gauge or sieve must be the dimensions specified in co1. Table 1 of 3 for optimal size of materials.

4. The total amount passing the gauge weighs at least 0.1 percent of the weight of the test specimen.

5. Fluidity Index is the total weight of the material passing through different thickness scales or sieves, expressed as a percentage of the total weight of the measured sample.

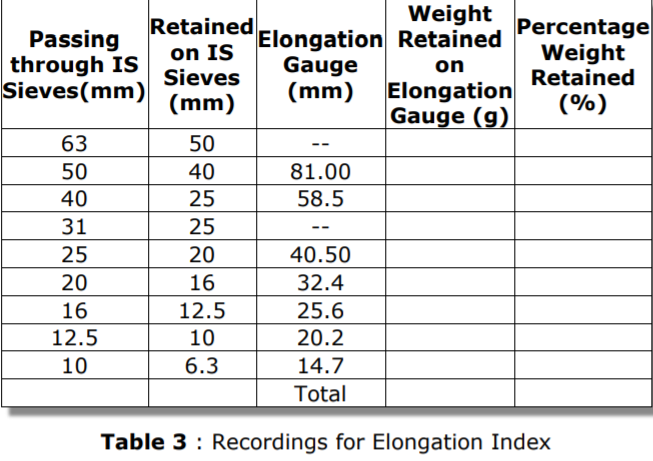

6. Longitudinal material separation – Each part is measured individually in a metal long gauge of the pattern shown in Figure 4. The gauge length used must be specified in co1. Table 1 of 4 for optimal size of materials.

7. The total amount retained by the long gauge weighs at least 0.1 percent of the weight of the test specimen.

8. The length index is that the total weight of the fabric preserved within the gauges of assorted lengths expressed as a proportion of the whole weight of the measured sample.

5. Observation And Recording:

6. Calculation:

1. The Flakiness Index on associate combination is =

Total weight passing Flakiness Gauge x one hundred / Total weight of check sample =_________(%)

2. The Elongation Index on associate combination is =

Total weight preserved on Elongation Gauge x one hundred / Total weight of check sample =________(%)

7. Video

Flakiness and Elongation Index

8. Also Read:

1. California Bearing Ratio Test On Soil