Vibration of concrete | Detailed Explanation

Vibration of concrete:

The process of compacting the concrete with vibration basically involves removing entrapped air and forcing the particles into a close configuration. Extremely dry and stiff mixtures can be satisfactorily vibrated so that, if compressed by hand, the desired strength given with a low cement content can be achieved.

This means a saving in cost, but against that, we have to offset the cost of the vibrating equipment and of heavier, more sturdy formwork. In any case, however, the cost of labor would probably be the deciding factor as far as the total cost is concerned.

Both manual compression and vibration compression can produce high-quality concrete, with the right mixing and performance. Similarly, both methods can produce poor concrete: in the case of hand-fired concrete, inadequate compression is the most common defect, in the case of vibration, inadequate vibration, or non-single compaction caused by isolation; The latter can be prevented by mixing harder and better grades.

The specified consistency of the mix governs the choice of the vibrator as, for example, mixes suitable for pumping may have too-wet a consistency for vibration.

Thus, for efficient compaction, the consistency of the concrete and the characteristics of the available vibrator has to be matched. Essentially. there are three basic methods of compacting concrete by vibration, and these are discussed below, There are variations of these types which have been developed for special purposes but they are beyond the scope of this book.

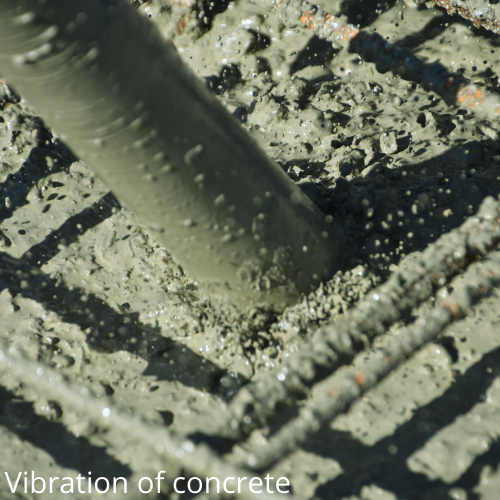

Internal vibrators:

Of the many types of vibrators, this is probably the most common. It consists of poker with an exotic shaft that runs through the motor’s flexible drive.

Poker is immersed in concrete and applies roughly harmonic forces to it; Therefore, the alternate names for the poker vibrator or immersion vibrator. The frequency of vibration usually varies between 70 and 200 Hz with an acceleration greater than 4 g.

The poker should be easily moved from place to place so that the concrete is vibrated every 0.5 to I m (or 2 to 3 ft) for 5 sec to 2 min, depending on the consistency of the mix. The actual completion of the concrete, which should be neither honeycombed nor contain an excess of mortar.

Also watch:

It is recommended to gradually withdraw the poker at the rate of about 80mm / sec (3 inches/second) so that the hole left by the vibrator is completely closed without any air being trapped. The vibrator must be sunk through the entire depth of the newly deposited concrete and into the bottom layer, and may still be plastic (see Figure 7.11).

In this manner, monolithic concrete is obtained, thus of compaction can be judged by the appearance | jo the surface SI SU avoiding settlement cracks, and the internal effects of the plane of weakness at the junction of the two layers, possible bleeding., It should be noted lift is greater than about 0.5 m (2 ft).

Vibrator layer. All work is done directly on concrete as it is relatively efficient. They are made in sizes up to 20 and are relatively inaccessible. However, the immersion vibrator does not expel air from the form boundary so ‘slicing’ with the form is necessary through the flat plate on the edge.

The use of absorptive linings to the form is helpful in this respect but expensive. other types, internal Vibrators ) utu in.) in diameter so that they are useful for heavily reinforced

External vibrators:

This type of vibrator is rigidly attached to the formwork, which rests on elastic support so that both the form and the concrete vibrate. As a result, a substantial proportion of the work done is used in vibrating formwork, which must be strong and tight to prevent deformation and leakage of the grout.

The principle of an external vibrator is the same as an internal one, but the frequency is between 50 and 150 Hz; Sometimes, manufacturers refer to the number of impulses, i.e. half cycles. Preliminary or thin external vibrators are used in situ sections that have a shape or thickness not suitable for internal vibrators.

Also Watch:

The concrete must be placed in suitable depth layers because the air is not expelled by the depth of the concrete, and the position of the vibrator may need to be changed as the concrete progresses. Portable, non-clamped external vibrators can be used in inaccessible sections, but their range of compression is very limited. One such vibrator is an electric hammer, sometimes used to compress concrete test specimens.

Also Raed: Manufacture of concrete