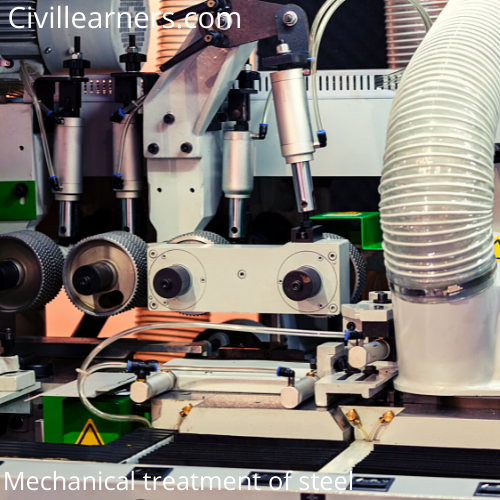

Mechanical treatment of steel:

The purpose of providing mechanical treatment to steel is to make steel available in the market by giving it the shape it needs. Mechanical treatment of steel can work hot or cold. Working hot is very common.

Following are those operations involved in the mechanical treatment of steel:

(1) Drawing

(2) Forging

(3) Pressing

(4) Rolling.

Each operation will now be briefly described.

(1) Drawing:

This operation is performed to reduce the cross-section and increase the length. In this operation, the metal is pulled through dice or specially shaped tools. The drawing is continued until the required diameter wire or cross-section is obtained. This process is used for making- wires and spokes.

(2) Forging:

The foraging operation is carried out by repeated blows under a power hammer or press. The metal is heated over a critical temperature range. It is then placed on the figure and subjected to a hammer blow.

This process increases the density and improves the grain size of the metal. Rewriting belongs to counterfeiting operations. This process is used for the manufacture of bolts, clamps, etc.

In the case of the former, steel is free to spread in all directions as it is hammered. In the latter case, steel flows under the blows of a hammer to fill the inside of a die, and the excess material is forced out through a special groove, and then it is cut off. Die-forged parts have very accurate dimensions.

(3) Pressing:

This is a slow process and is carried out on devices called presses. The main advantage of this process is that it does not involve any trauma. The press mainly consists of die and punch.

Die and punch arc in the appropriate shape to get the article of the desired shape. The metal is placed on the die and then the punch is dropped under heavy pressure. The metal is thus pressed between the die and the punch and an article of the desired shape is obtained.

For preparing articles with wide changes of shape1 pressing is to be carried out in different stages. This process is helpful when a large number of similar engineering articles are to be produced.

( 4) Rolling:

This operation is carried out in specially made rolling mills. Ingots, when the still red is hot, are shipped sequentially through various rollers until the articles of desired shapes are obtained.

A variety of shapes such as angles, channels, flats, joists, rails, etc. are obtained by the rolling process. It is also possible to make jointless tubing with the help of this process. Bored with rollers in stages until a solid rod gets the required diameter and thickness of the pipe.

Also Read: Defects in steel

Also Read: Manufacture process of steel