Manufacture of Portland cement

Following are the important operations involved in the manufacture of portland cement:

1) Mixing of raw materials

2) Burning

3) Grinding

4) Packing of cement

|

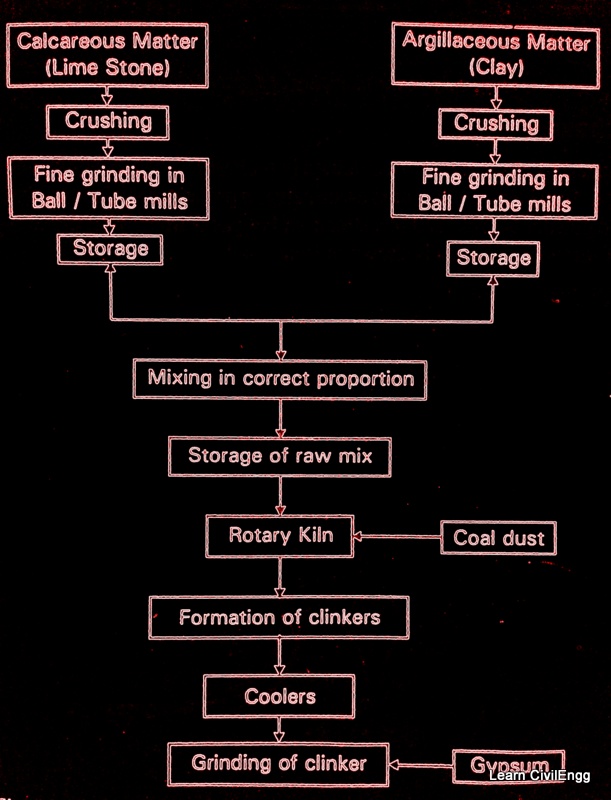

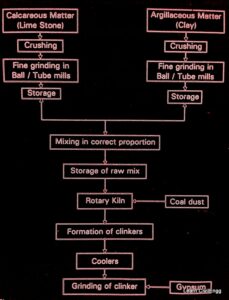

| Flow chart for manufacturing of cement |

Mixing of raw materials:

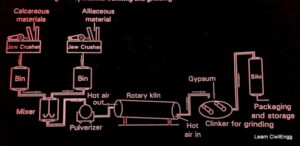

The processes used for the manufacture of portland cement can be classified as dry and wet.

In dry process. The raw materials are first reduced in size of about 25mm in crushers and Crushed material is ground to get fine particles into ball mill or tube mill.

Each material after screening is stored in a separate hopper. The powder is mixed in require proportions to get a dry raw mix which is stored in silos (storage tank) and kept ready to be fed into the rotary kiln.

Raw materials are mixed in required proportions so that the average composition of the final product is maintained properly.

In modern factories, the feed is preheated to a certain extent in a precalcinator before being fed into the kiln by means of a secondary furnace.

The raw materials are fed into the kiln via a multiple-stage suspension pre-heating system. The dry mixture is pre-heated by direct contact with the waste gases in a two or four-stage cyclone system. The gases and raw feed move counter-currently. The raw feed attains a temperature of about 180°C and is then directly fed into the rotary kiln. The gases leave the cyclone at 300-350°C.

In the wet process, water is added at this point to obtain a blended mixture of very finely ground raw materials and water, called slurry. The slurry is stored in tanks under constant agitation and fed into huge firebrick-lined rotary kilns

In India, the wet process has been replaced to a wide extent by the dry process, mainly for fuel and heat economy. However, air pollution is reduced in the wet and semi-dry processes.

Dry process(modem technology) is now preferred and adopted in most of the cement industries due to the following reasons :

a) The coal consumption in the dry process is approximately one-fourth of that in the wet process.

b) The blending of dry powders has now been perfected and the wet process which requires much higher consumption of power can be replaced with confidence.

c) The application of modern technology has made the production of cement by a dry process more economical and of superior quality.

Significant advancements have been made in raw material grinding, preheating, controlled clinker cooling, cement grinding, and packing technologies with advanced process control and instrumentation system in recent years.

The kilns are fired with crushed coal or gas from the discharge end under a forced draft so that material being fed in advances against the heat blast as the kiln rotates.

Also read: Important Concept of Hydration of cement

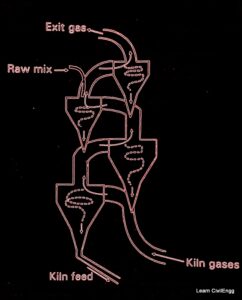

Cyclone preheater for Manufacturing of cement:

The raw materials are preheated or calcined in a preheater or series of cyclones before entering the rotary kiln. A preheater also called a suspension preheater is a heat exchanger in which the moving crushed powder is dispersed in a stream of hot gas coming from the rotary kiln. The common arrangement of series of cyclones Is in the below image.

The heat transfer of hot kiln gases to raw material takes place in co-current. The raw materials are heated up to 800°C within less than a minute. About 40% of the calcite is decarbonated during heat transfer.

The quality and quantity of fuel used in the kiln can be reduced by introducing a proportion of the fuel into the preheater. 50 – 65 % of the total amount of fuel is introduced into preheater or precalciner which is often carried out by hot air ducted from cooler.

The fuel in the recliner is burnt at a relatively low temperature, there so heat transfer to the raw material is very efficient. The material has a residence time in the hottest zone of a few seconds and its exit temperature is about 900°C, 90-95% of calcite is decomposed. Ash from the fuel burn in the precalciner is effectively incorporated into the mix.

Advantages of precalination:

- Decrease the size of the kiln.

- Decrease in capital cost.

- Increase in rate of material passes to the kiln.

- Decrease in rate of heat provided which ultimately lengthens the life of the refractory lining.

For better Understanding Watch the below video:

Burning:

Burning is carried out in a rotary Kiln which is rotating at 1-2 rpm at its longitudinal axis. rotary kiln is steel tubes having diameters in between 2.5-3.0 meters and length varies from 90-120 meters.

The inner side of the kiln is lined with refractory bricks. The kiln is rested on roller bearing and supported by columns of masonry or concrete in a slightly inclined position at a gradient of 1 in 25 to 1 in 30.

The process of burning is explained below (manufacture of portland cement):

- The raw mix or collected slurry is injected into the kiln from its upper end.

- Burning fuel like powdered coal or oil or hot gases is forced through the lower end of the kiln so long hot flame is produced.

- Due to the inclined position and slow rotation of the kiln, the material charged from the upper end is moving towards the lower end (hottest zone) at a speed of 15meter/hour. As gradually descends the temperature rise.

- In the upper part, water or moisture in the material is evaporated at 400°C temperature, so it is known as the drying zone. In the central part (calcination zone), the temperature is around 1000 C. in the form of small lumps called nodules. where decomposition of limestone takes place. After escapes of CO., the remaining material

· The lower part (clinkering zone) has a temperature between 1500-1700C where lime and clay are react to yielding calcium aluminates and calcium silicates. These aluminates and silicates of calcium fuse to gather to form small and hard stones are known as clinkers. The size of the clinker is varying from 5-10mm.

As clinkers are coming from the burning zone, they are very hot. The clinkers are cooled down by admitting countercurrent direction at the base of the rotary kiln. Resulting hot air is used for burning

powdered coal or oil and cooled clinkers are collected in small trolleys or in a small rotary kiln.

Grinding:

Cooled clinkers are ground to a fine powder in the ball mill or tube mill. 2-3% powdered gypsum is added as a retarding agent during final grinding. So that, resulting cement does not settle quickly, when comes in contact with water.

After the initial set, the cement-water paste becomes still, but gypsum retards the dissolution of tri-calcium aluminates by forming tricalcium sulfo aluminate which is insoluble and prevents too early further reactions of setting and hardening.

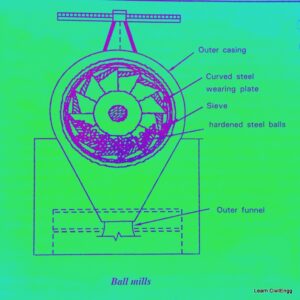

Ball mills:

These mills are used to carry out grinding of raw materials or a mixture of raw materials or clinkers.

The material to be ground is fed from the top. When the mill is rotated about its horizontal axis, the steel balls strike against the perforated curved plates due to which they crush the material.

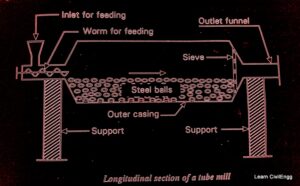

Tube mills:

It is in the form of a long horizontal steel cylinder of diameter about 1.5m and length 7m to 10m. The cylinder is filled partly with steel balls of size varying from 20mm to 26mm.

The material to be ground is fed from the inlet. Fine grinding is achieved due to steel balls of smaller size. The ground material is collected at the outlet funnel.

Packing of cement:

· Cement can be packed in 25 kg, 50 kg, Jumbo bags (1 ton) or bunkers, depending upon the customer’s requirement. The most common being a 50 kg pack.

· Cement is available in either Poly Propylene (PP), Paper bags, or PP laminated bags (stitched or pasted).

· The size of packing for different types of cement varies with the fineness of the cement. Finer the cement, the bigger will be the size of the bags.

· Typical printing on the bag contains ISI mark, license no. grade and type of cement, brand logo, net weight of cement in the bag, week, month, year, name of the organization, address of the manufacturing plant, MRP.

· Computerized loading and packing unit is employed in modern cement manufacturing plants.

Also read: Important concept of composition of cement

Cement products:

The cement then is used for several engineering purposes and for further manufacturing of cement and products.

Following are some of the cement products available in the market:

- · Hollow and Solid cement blocks.

- · Precast concrete materials.

- · AC sheets and pipes.

- · RCC Door and window frames.

- · RCC spun pipes.

- · Manhole covers.

- · RCC air ventilators.

- · Ferroconcrete cupboards.

- · Design pillars, RCC molds, Grills.

- · Design tiles for walls and Roofing, etc.

Thank you guys for reading this article on ‘manufacture of portland cement’ read more if you like.