Manufacturing of Ceramic tiles | Complete process | Operation – civillearners

Definition of Tiles:

The manufacturing ceramic tiles are used for various purposes in the building industry. They are thinner than bricks and hence should hr carefully handled to avoid any damage to them.

Manufacture of tiles Ceramic, mosaic tiles, etc:

Following four distinct operations involved in the general process:

1) Preparation of clay

2) Moulding

3) Drying

4) Burning.

Each operation will now be briefly treated.

1) Preparation of clay:

The selected clay is taken and free from any impurity such as grit, pebbles, etc … such clay is then pressed and turned into fine powder in pug mills. For high-quality edges, a large amount of pure water is added to crushed clay and it is mixed well into the tank.

The mixture is then allowed to stand quietly. Coarse heavy particles settle in the bottom of the tank. The fine particles are taken into other bins and the water is allowed to dry.

The best clay used after such a process for making tiles, a mixture of ground glass and pottery ware can be added to the edges of the clay to make the edges harder and intrusive.

2) Moulding:

The clay is placed in molds that represent the type or shape the tile is to be created. Molding can be done with the help of wood molds or mechanical means or by a potter’s wheel.

Wood molds should be made from well-spiced wood. The clay is pressed in such molds. And when the soil is removed from the mold the edges are ready to dry.

Care should be taken to preserve the shape of the edges when removing molds. Molding involves the provision of machinery with the help of mechanical means and clay is pressed into such machines to obtain the desired section and edges of shapes.

The molding method of the potter’s wheel is similar to the method used by the potter in making pottery. This method is adopted when the tile is circular while on the wheel. However, it may have a diameter along with it.

3) Drying:

The edges, as they come out of the mold, lay flat on top of the appropriate number. Thus different piles are formed. After about 2 days, irregular [edges rare due to warping is fixed with Fiat wood mallet.

They are only lifted when the edges are hardened by hand. The edges and undersides are swatched. They are attached to the edge of the shade to dry for about two days.

The tiles are drying in the shade and the sun and rain prevent the edges from cracking and warping.

4) Burning of Ceramic tiles:

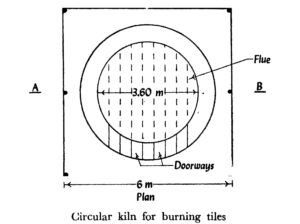

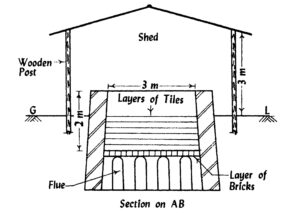

Tiles are then burnt in kilns. A typical kiln for accommodating about 30000 to 40000 tiles as shown in fig.

It is circular in shape and is protected by a shed. A layer of tiles is laid flat on the rows of long. Burning is affected if firing wood is placed in.

These flues. Bricks are arranged in such a way that the open spaces between them remain. On top of the bricklayer, the dried edges are placed over the edge layer by layer. Closing the vents is affected by the brickwork in the soil. The top of the nest is loose in the layer of old edges.

Heat control is important to achieve good results. The fire is initially quiet. It removes moisture. It is then raised to about 800. C. It is let loose for about 6 hours and raised to white heat again, bringing the temperature to 1300. C. This temperature is maintained constant for 3 hours.

The process of loosening the fire for 6 hours and then increasing the temperature to white heat is repeated. White heat is maintained for 4 hours. Finally, the flues are filled with fuel and the doors are closed with brickwork in the mud. The kiln then gradually allows cooling. It takes about 72 hours to complete the process of burning the tiles.

The edges are removed from the nest. Underburned tiles are sorted and placed on top of the nests to burn the edges.

Also Read: Terra cotta article, I am sure you will love it

Characteristics of a good tile:

1) It should be free from any cracks, defects, or bends.

2) It should be regular in shape and size.

3) It should be sound, tough, and durable.

4) It should be burned well.

5) It should give a clear ringing sound when hit by the hand or the other or with a light hammer.

6) It should fit properly when placed in position.

7) It should give an equal and compact structure when viewed on its broken surface.

8) It should have a uniform color.

Also Watch:

Conclusion:

Here we have studied the clay manufacturing, moulding, drying, burning process of ceramic tiles. Thank you for reading this article, I hope this article may give the information which will you require.

Also, read Manufacturing Process